-

You are here:

- Home

Characterization Laboratory

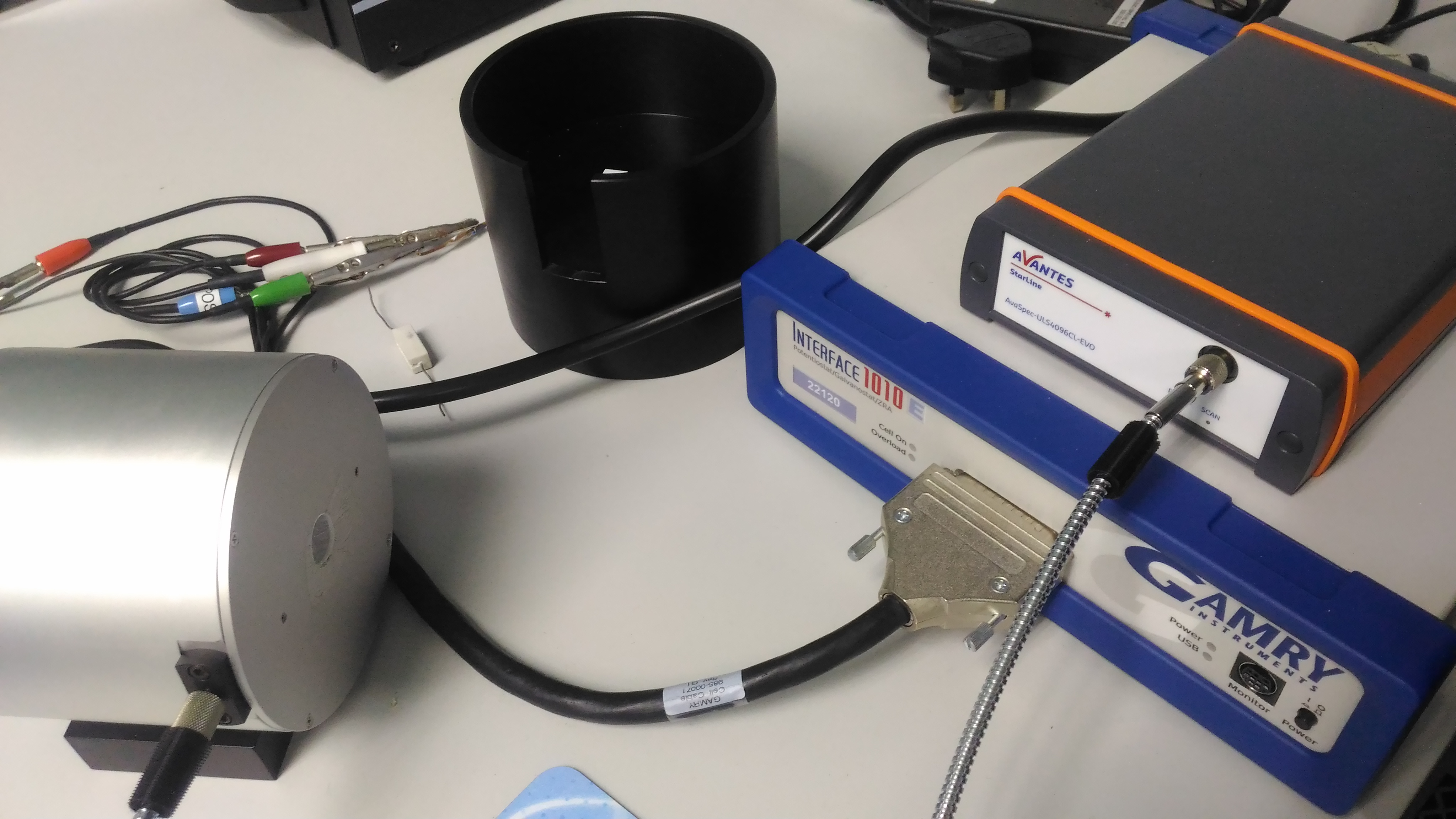

ELECTROLUMINESCENCE PIC : Rahmawatini Abdul Rahman Tel : +604-653 5650 Email : rahmawatini@usm.my

GENERAL DESCRIPTION

Electroluminescence is a phenomenon of certain materials such as semiconductors that causes the material to emit light due to a strong electric field or passage of an electric current. Electroluminescence lead a direct conversion of electric energy to light without generation of heat.

SYSTEM FEATURES

- AVASPEC-ULS4096CL-EVO

- Optical Bench: ULS Symmetrical Czerny-Turner, 75 mm focal length

- Wavelength range: 200-1100 nm

- Resolution: 0.05-20 nm, depending on configuration (see table)

- Stray-light: 0.19-1.0%, depending on the grating

- Sensitivity: 218,000 counts/µW per ms integration time

- Detector: CMOS linear Image Sensor

- INTERFACE 1010E

It is a full-featured potentiostat capable of performing all techniques, including electrochemical impedance spectroscopy.

- Max Applied Current - ±1 A

- Maximum Applied Potential - ±12 V

- EIS 10 μHz - 2 MHz

- POWER SUPPLY PS-12VDC/2.08A

- PS-12VDC/5.0A for HSC NIRLine and SensLine TEC-EVO

- INTERFACE CABLES

- AVASPEC PRODUCT CD-ROM

APPLICATION USED

- LEDs

- Backlights

- Liquid crystal displays

- Night lamps

- Electroluminescent lighting

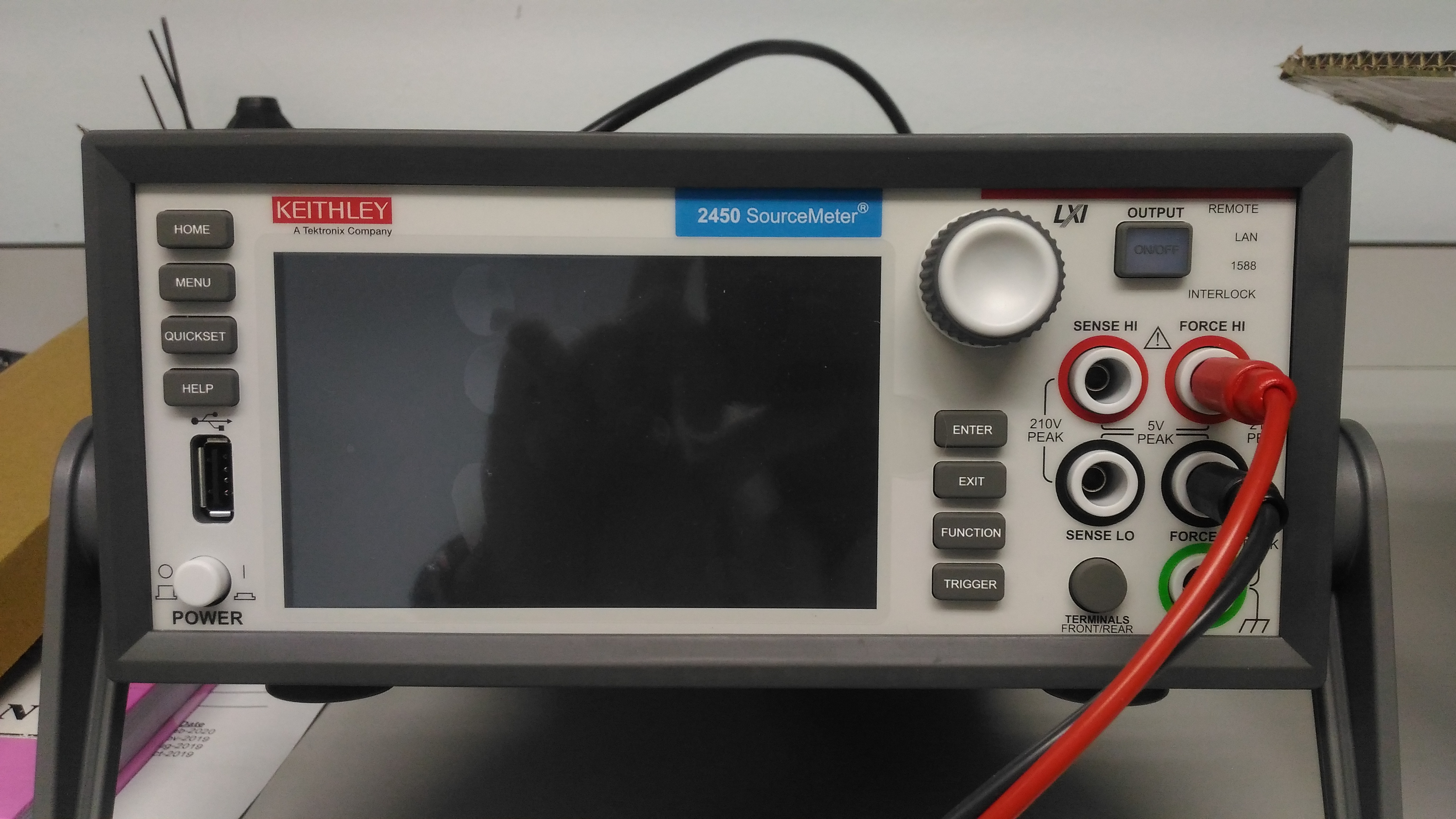

KEITHLEY SYSTEM SOURCEMETER

General Description

The Model 2450 is Keithley’s next-generation SourceMeter source measure unit (SMU) Instrument that truly brings

Ohm’s law (current, voltage, and resistance) testing right to your _ngertips. Its innovative graphical user interface (GUI)

and advanced, capacitive touchscreen technology allow intuitive usage and minimize the learning curve to enable engineers

and scientists to learn faster, work smarter, and invent easier.

SYSTEM FEATURES :

– V-Ranges: 20mV – 200V

– I-Ranges: 10nA – 1A

– 0.012% Basic Accuracy

– Wideband Noise: 2mVrms Typ

– Sweep Types: Linear, Log, Dual Linear, Dual Log, Custom, Source-Memory (SCPI 2400 Mode)

– >250,000 Point Reading Bu_er

– >3000 Readings/Sec.

– SCPI (2400 + 2450) + TSP Programming

– GPIB, USB, Ethernet (LXI)

– Front: Banana Jacks, Rear: Triax

– Temperature Coe_cient (0°–18°C and 28°–50°C): ±(0.15 × accuracy speci_cation)/°C

MAX. OUTPUT POWER:

- 20W, four-quadrant source or sink operation.

SOURCE LIMITS:

- Vsource: ±21V (_ 1A range), ±210V (_ 100mA range)

- Isource: ±1.05A (_ 20V range), ±105mA (_ 20V range)

OVERRANGE: 105% of range, source and measure.

LOAD IMPEDANCE:

- 20nF typical (standard). Stable into 50_F typical

(High-C mode).

- High-C mode valid for _100μA ranges, _200mV ranges.

MAX. VOLTAGE DROP BETWEEN FORCE and SENSE

TERMINALS: 5V.

APLICATION USE

– Ideal for current/voltage characterization and functional test of a wide range of today’s modern electronics and devices, including: Nanomaterials and Devices, Semiconductor Structures, Organic Materials and Devices, Energy Efficiency and Lighting, Discrete and Passive Components, and Material Characterization

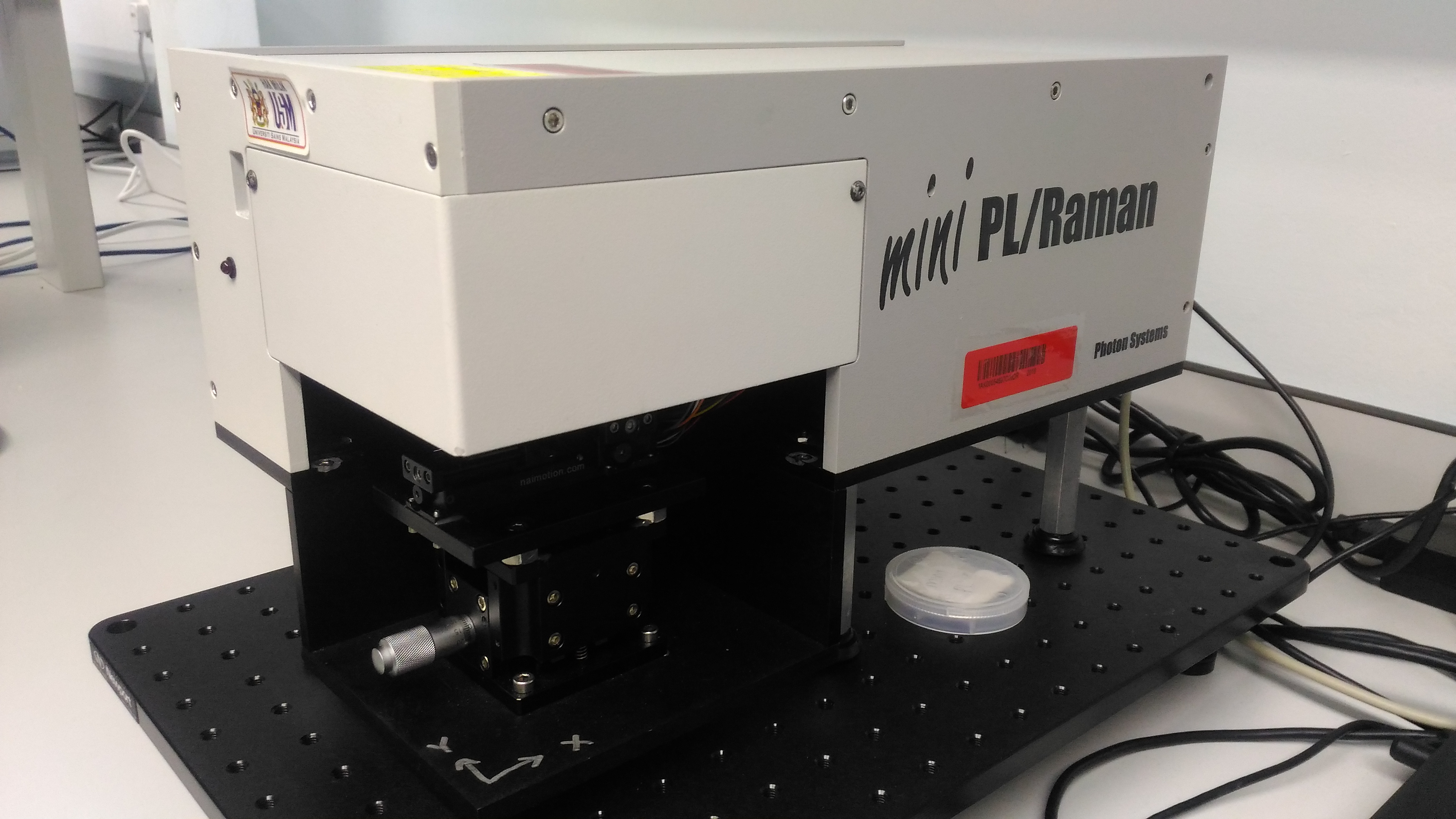

MINI PL/ RAMAN PIC : Rahmawatini Abdul Rahman Tel : +604-653 5650 Email : rahmawatini@usm.my

GENERAL DESCRIPTION

The most compact and lowest cost of deep UV (224nm or 246.8nm).

Measurement of photoluminescence (PL) spectra from semiconductor materials is an important characterization method and is widely accepted for providing information on carrier doping levels, alloy composition, bandgap, and edge effects, etc. The ability to measure UV Resonance Raman spectra adds specificity and enhanced characterization of materials. These measurements are important both for research, device characterization and process monitoring.

Photon System Deep UV (DUV) Mini PL/RAMAN Spectrometer provides the most compact and inexpensive instrument available at these wavelengths. Enabling PL and Raman spectra measurement of semiconductor materials with bandgap up to about 5.5 eV corresponding to AlGaN with Al concentrations up over 80%

SYSTEM FEATURES

- Room temperature PL and Raman

- 5.5 (224nm) or 5.0 eV (248.6nm) laser excitation

- Measurement of excitation and emission energy for direct QE measurement

- Highly portable 15x18x36cm, <8kg

- High-resolution 0.2nm (multi slits included)

- Computer controlled grating selection and calibration.

- 1200g/mm grating std (300nm peak)

- 3600g/mm grating for High Res PL or Raman optional (250nm peak)

- Digital PMT controller with gated box car Integrator & Averager for low noise digital PMT output measurement.

- <20Watts (90-240VAC) input

- Fully integrated, self-contained, system

- Lab View interface and control of laser, spectrograph, PMT, spectral data

- Analysis software included, FWHM, peak, side lobe identification, spectral subtract, normalize, etc.

- Up to 50mm diameter sample size

- X-Y-Z stage manual sample control 50mm standard

- 50mm X-Y motorized stage including mapping software optional.

APPLICATION USED

Using an ultraviolet spectroscopies, this is particularly useful in the characterization of semiconductor materials and can provide information directly related to the optical properties of the sample.

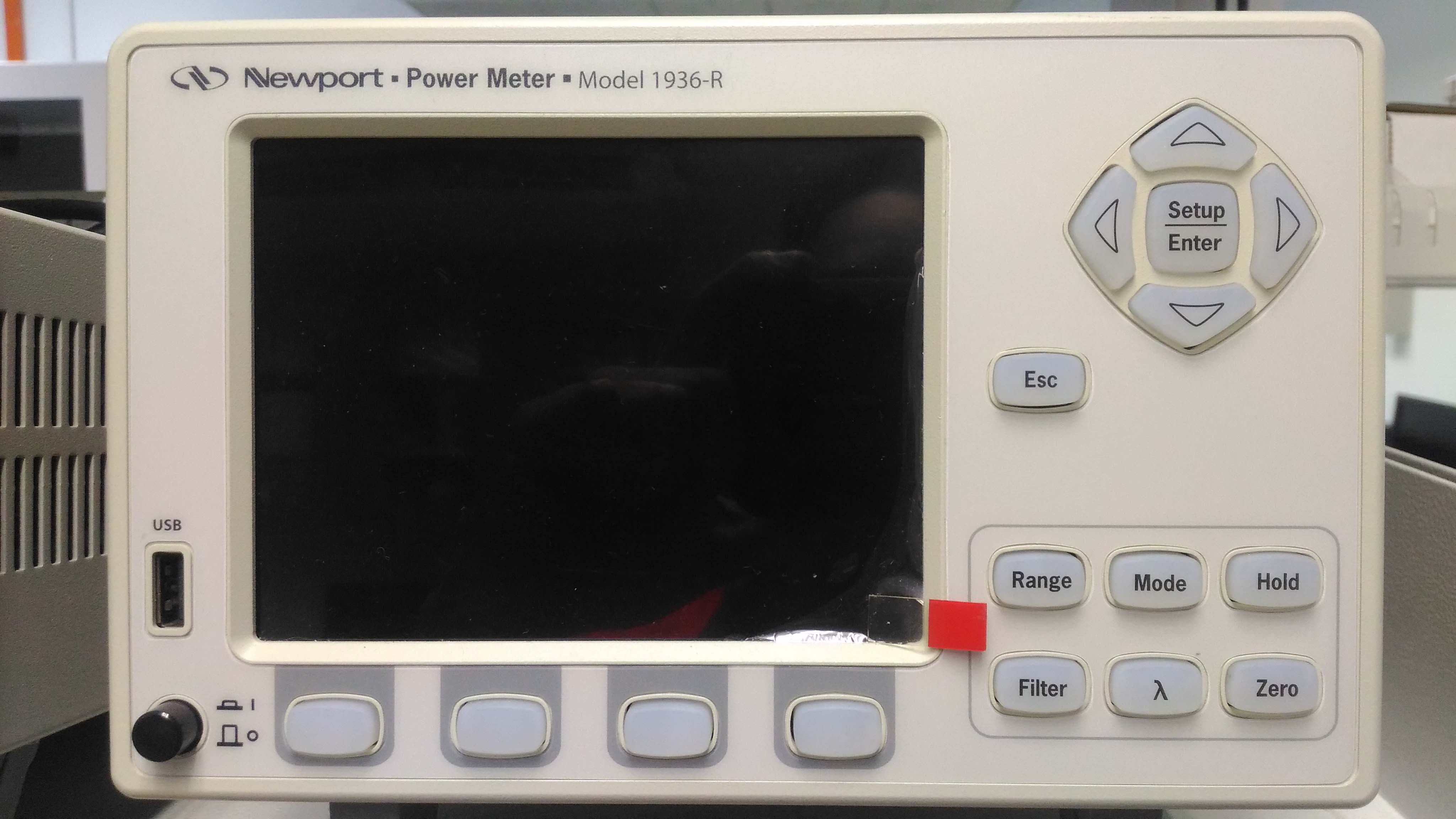

NEWPORT POWER METER (MODEL 1936-R (Optical)

GENERAL DESCRIPTION

The 1936 Series Optical Meters are designed to provide a powerful combination of features to measure optical power and energy of near monochromatic or monochromatic sources. Use of the extensive measurement modes and features have been simplified with an intuitive menu driven structure that provides quick access to all modes, features and settings.

- Most advanced optical power and energy meters in the market

- Ideal for high speed, modulated light measurements

- Data acquisition rate up to 10 kHz to on-board memory

- Sub-picowatt noise level with photodiode detectors

- Five analog and five digital filter settings

- Trigger-in and trigger-out for synchronized measurements

SYSTEM FEATURES

- Sampling Rate: 250 kHz (10 kHz accessible by user)

- Compatible Detectors: 818-xx/DB, 918D (photodiode), 818P, 919P (thermopile), 818E (pyroelectric), 819C, 819D

- Data Storage: 250,000 Point Internal Storage

- Analog Output: 0-1 V, 0-2 V, 0-5 V or 0-10 V (user selectable output impedance)

- Bandwidth: Up to 500 kHz (Photodiode), Up to 1.9 MHz (Thermopile or Pyroelectric) depending on Range

- Accuracy: ±0.2 % for CW, ±1 % for Peak to Peak, Pulse to Pulse, and Integration Mode

- Detector Input: Up to 25 mA for photodiode, 130 V for thermopile and pyroelectric detectors

- Display Mode: 20 mm Numeric, Bar Chart, Min/Max Bar, Statistics, Analog Needle

- Display Type: 5.7 in. Graphical TFT LCD, ¼ VGA

- Display Refresh Rate: 20 Hz

- Photodiode Measurement: Average Power, Peak-to-Peak Power, Frequency

- Thermopile Measurement: Average Power, Single Shot Energy

- Frequency Measurement Range: 1 Hz - 250 kHz

- Measurement Rate: Up to 10 kHz pulses for pyroelectric, Up to 20 kHz for photodiode (peak to peak measurement)

- Resolution: 0.0004% of Range Full Scale

- Power Requirements: 90-240 VAC

- Operating Temperature: 5 to 40°C, <70% RH

APPLICATION USED

Electrical equipment for measurement, control and laboratory use in industrial locations.

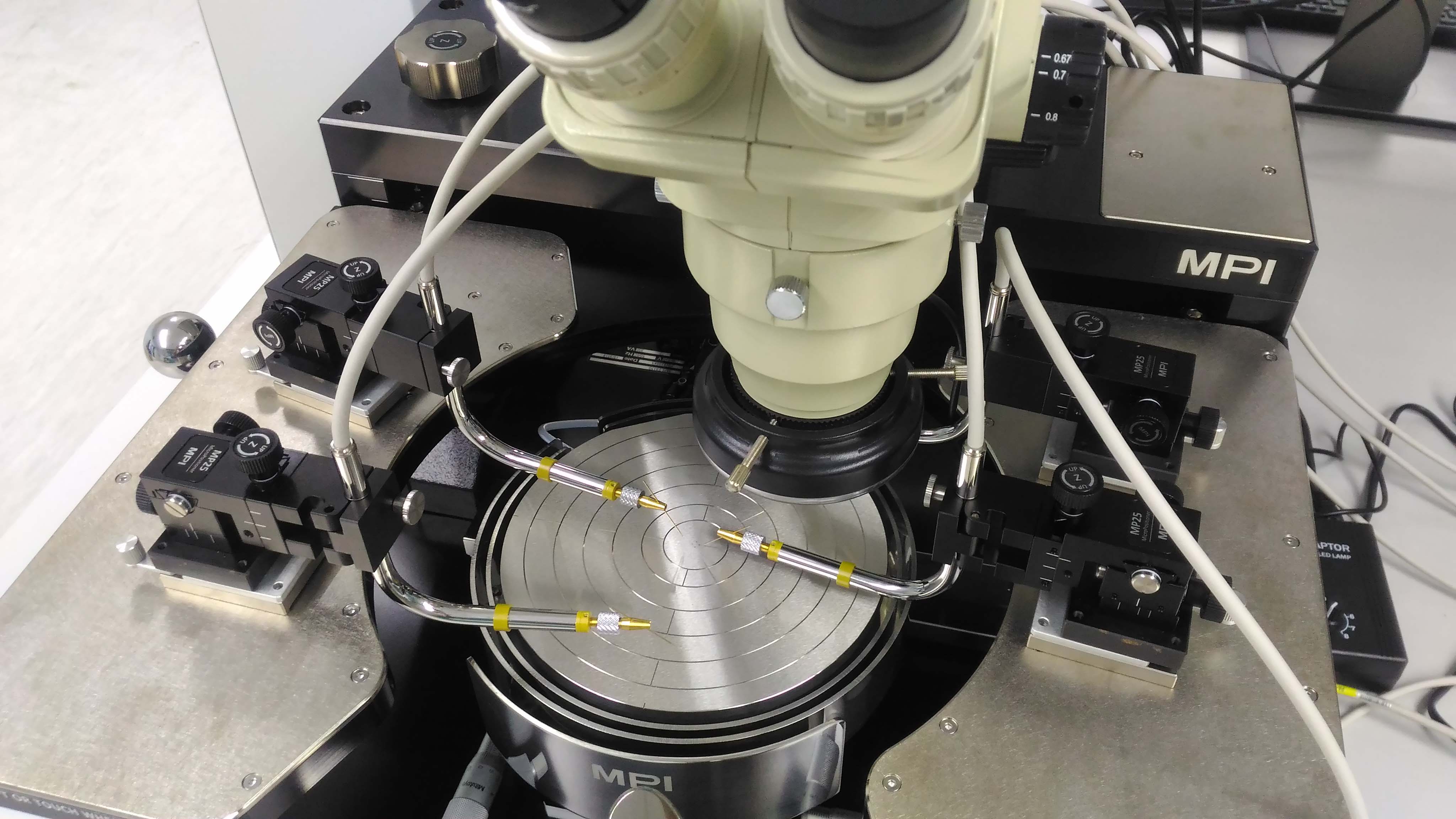

PROBE STATION [QUICK TEST]

APPLICATION USED

MPI TS150 150 mm Manual Probe System- Designed for wide variety of applications such as Device Characterization and Modeling, Wafer Level Reliability, Failure Analysis, IC Engineering, MEMS and High Power.

SYSTEM FEATURES

Ergonomic Design

-

- • Unique puck controlled air bearing stage for quick single-handed operation

- • Rigid platen accommodates up to 10 DC or 4 RF positioners

- • Highly repeatable platen lift design with three discrete positions for contact, separation, and loading

Upgradability

- • Available with various chuck options and wide range of accessories such as DC/RF/mmW MicroPositioners, Optics, microscopes and EMI shielded dark box to support various application requirements.

APPLICATION USED

For accurate and reliable DC/CV, RF and High Power measurements.

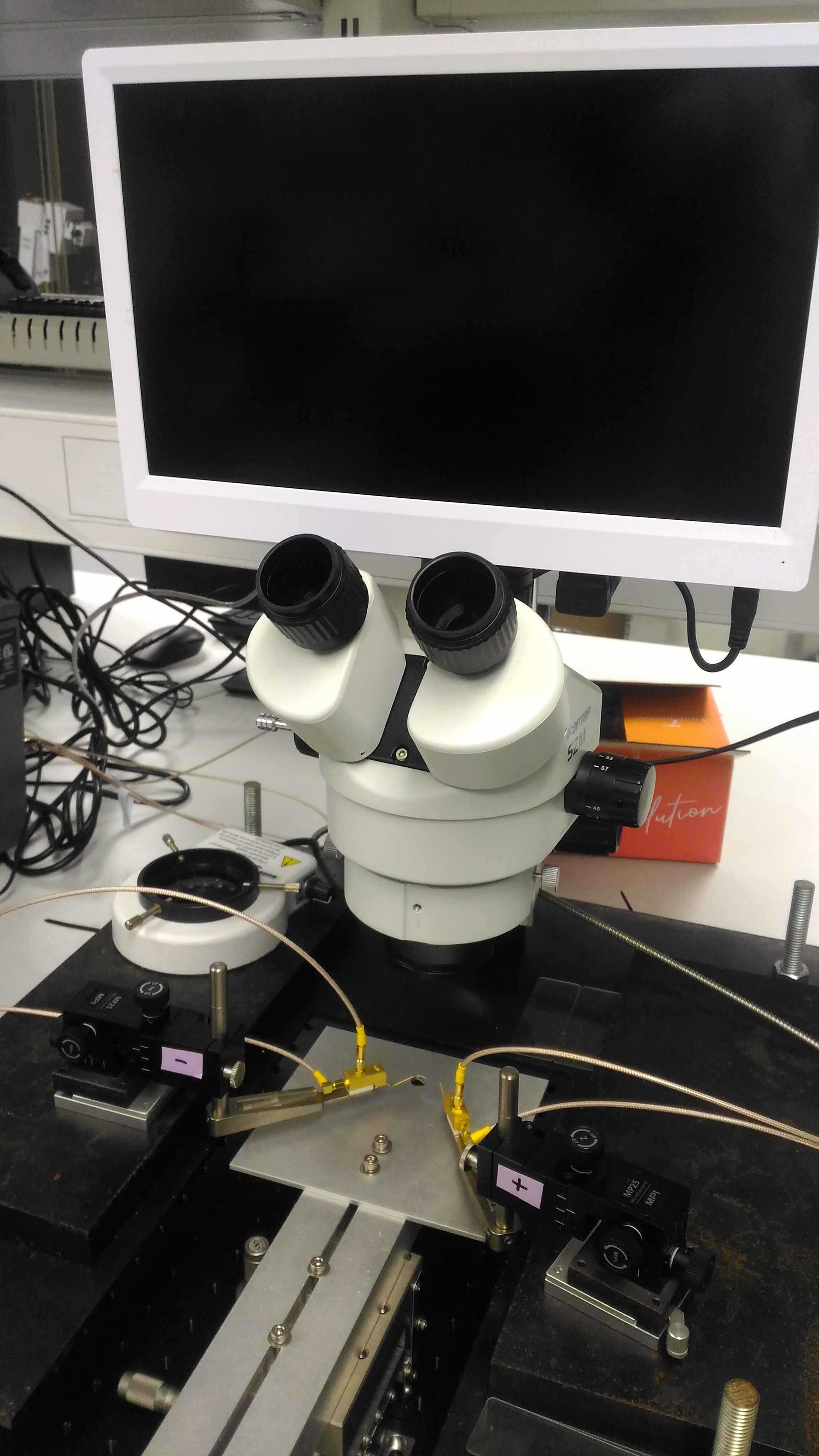

PROBE STATION WITH MICRO-POSITIONER

DESCRIPTION

Probe stations enable physical scientists and researchers to conduct fundamental science through convenient, repeatable measurements producing consistent results. Probe stations are versatile and flexible research platforms that can be used in dedicated applications or as multi-use community research assets.

SYSTEM FEATURES

MANUAL PROBE STATION

- Affordable manual probing equipment

- Test individual die, partial or full wafers

- Systems for 50, 100, 150 and 200mm Wafers

- DC or HF base configurations

- Designed for Universities & Research Personnel

- Very simply to setup and operate

- Robust small footprint design

- Extensive options: thermal chucks, dark box, manipulators etc.

The LAB Assistant is an affordable manual wafer probe station designed for research centres, universities, teaching laboratories and low volume production environments. The system features a robust design in a small footprint and includes all the options required to start manual probing of wafers or devices, "out-of-the-box".

The LAB Assistant's range of manual probe stations are available in either DC or HF configurations, for probing of individual die or partial wafers, through to 200mm diameter wafers.

An extensive range of additional options can be added, including Dark Boxes, Thermal Chucks, CCTV Systems, Manipulators & Probe Arms, Probe Card Holders, Compound Microscopes and Vibration Isolation Tables etc.

LAB Assistant Probe Stations standard features:

- Rigid aluminium base with rubber vibration isolation feet

- 50x75mm Coaxial Microscope Stage

- Trinocular Stereozoom Microscope

- DC or HF Manipulators & Probes

- Grooved Vacuum Chuck suitable for die or partial wafers

- Magnetic X-Y-Z Stage with micrometre adjustments

- 360 degree Coarse & 10 degree fine theta adjustment

- Compact small footprint

- Complete system ready to probe out of the box!

APPLICATION USE

A mechanical probe station is used to physically acquire signals from the internal nodes of a semiconductor device. The probe station utilizes manipulators which allow the precise positioning of thin needles on the surface of a semiconductor device.

PROSKIT TEMPERATURE-CONTROLLED SOLDERING STATION PIC : Rahmawatini Abdul Rahman Tel : +604-653 5650 Email : rahmawatini@usm.my

GENERAL DESCRIPTION

- Compact digital soldering station with precise Celsius or Fahrenheit temperature adjustment. Temperature range from 200 to 480°C (392 to 896°F).

- Pro'sKit SS-207B is a compact digital soldering station with precise temperature adjustment for repairing the cell phones and other small electronics.

- Adjustable precise temperature control

- Insulated and ergonomic soldering iron handle.

- Compatible with a wide range of soldering iron tips

SYSTEM FEATURES

- Adjustable temperature control with lock/set screw.

- Temperature range 200- 480°C (392-896°F).

- Soldering iron handles are insulated and ergonomic-designed for ease

and comfort. - Celsius or fahrenheit temperature setting.

- Control IC modular design for easy and quickly repair.

- Power Consumption: 60W

- Output voltage: 24VAC

- Display: Digital

- Heater: Normal Heater

- Temperature range: 200°C- 480°C (392°F-896°F)

- Station Size(mm): 115x95x130

- Voltage: AC 110V/220V switch

- Standard Plug: B type, and extra conversion plug to A type

- Replacement heater: 9SS-900-HT

- Replacement Handpiece: 5SS-200-IRON

APPLICATION USED

- Mobile and radio systems devices repair.

- Cellular phones, PDAs, handhelds, laptops, notebooks, and motherboards repair.

- LAN, network nodes, and military communications systems equipment repair.

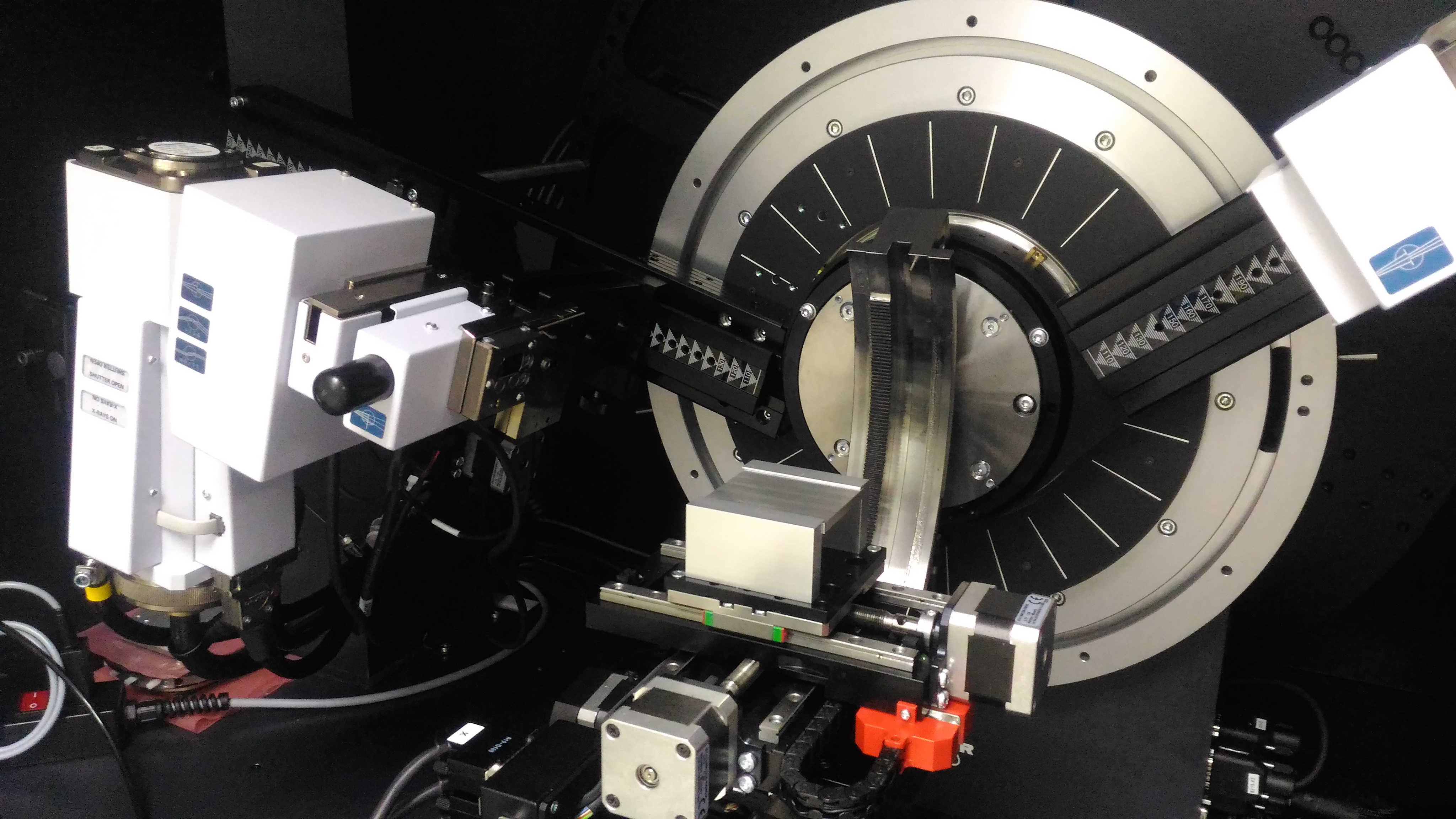

X-RAY DIFFRACTION SYSTEM (XRD) PIC : Azraai Fahmi Hamzah Tel : +604-653 5646 Email : azraai@usm.my

GENERAL DESCRIPTION

D8 DISCOVER BY BRUKER, materials analysis, by means of X-rays, covers almost every scientific field. This also includes compelling research areas like nanomaterials, photonics, microelectronics, energy generation and storage, soft matter.

The enormous breadth of research areas results in a wide variety of materials properties:

Consistency: solids, liquids, gels, powders, faults, defects

Size: from barely visible to large machined parts

Nano-scale order: from amorphous to long-range perfect order, and anywhere in-between

Orientation: from random, epitaxial to single crystal

Composition: chemical, crystalline phases

Quality: porosity, faults, voids, defects, strain

SYSTEM FEATURES

- True plug’n’play functionality with fully automatic component recognition and configuration

- Alignment-free switch of configurations – whatever your sample, whatever your application

- Absolutely open design with maximum flexibility for future adaptation

- Ultimate X-ray, machine and electric safety in compliance with the latest directives

- Audit-proven quality management system

- Ergonomic, clearly visible fail-safe warning and operator control elements

- Traceable measurement conditions – experiments can be repeated years later with exactly the same instrument configuration and measurement parameters

- Fast and cost-efficient technical service or analytical support thanks to remote control access

- Solid and maintenance-free goniometer design for mechanical strength and long life

- Instrument performance verification with NIST corundum standard SRM 1976a

- Instrument alignment ≤ ±0.01° 2 θ over the whole angular range

- Optional IQ/OQ procedures for regulated industries such as the pharmaceutical industry

- LYNXEYE compound silicon strip detector with all channels fully functional

- VÅNTEC-1 and VÅNTEC-500 detectors with patented MIKROGAP technology for large 1-D and 2-D coverage respectively without defective areas

- Choice of 2- and 4-bounce Ge channel-cut monochromators to tune the resolution

- LYNXEYE in 0-D mode and rotated 90° to cover an extremely large dynamic range

- Patented PATHFINDER optics for push-button switching between a high resolution and two high-flux beam paths

- Wafer mapping

- High-resolution reciprocal space mapping with 0-D detectors

- Fast reciprocal space mapping with LYNXEYE and VÅNTEC-1 1-D detectors

- VÅNTEC-500 2-D detector for ultra-fast reciprocal space mapping

- X-ray diffraction topography for imaging based on diffraction contrast

- Non-ambient measurements with dome heating stages between –100°C and 1400°C

- Temperature-dependent reflectometry from –180°C up to 800°C

- 1-D LYNXEYE and VÅNTEC-1 detectors for both scanning and SNAPSHOT mode

- Motorized tilt stage with two tilt axes, ± 7.5° each

- POLYCAP or MONTEL point focusing optics for in-plane measurements

- LYNXEYE and VÅNTEC-1 1-D detectors rotated 90° to collect GISAXS signal in scanning mode

- VÅNTEC-500 2-D detector to collect GISAXS signal in SNAPSHOT mode

- POLYCAP lens for high-speed, high-flux texture or stress analysis

- Intelligent setup of measurement schemes with DIFFRAC.WIZARD

- Texture determination based on the component method or the traditional spherical harmonics method

- Stress measurements in iso-inclination uniaxial shear (omega) or side-inclination (psi) mode

- Ultra-fast 2-D stress measurements with the VÅNTEC-500

- Residual stress determination according to the traditional sin²(psi) method as well as the multi hkl evaluation method

- From normal and shear stress up to the complete stress tensor

- Patented Laser-Video system for exact sample positioning

- MONTEL mirror for highest flux on small spot

- Tool-free, reproducible collimator exchange for ultra-fast beam size optimization

APPLICATION USED

Depending on the sample properties, particular parameters can be determined by X-ray analysis:

- Thickness, composition, mismatch, relaxation, and defects of epitaxial layers

- Thickness, roughness, and density of crystalline or amorphous layers

- Orientation identification and quantification of crystalline, textured layers or bulky samples

- Residual stress in crystalline layers or bulky samples

- Qualitative and quantitative phase composition, d-spacings and strains of crystalline powders and bulky samples

- In addition, the reaction of the parameters to environmental conditions such as temperature, pressure, humidity, applied voltage or stress, etc. can be investigated